In an electrical system, a short circuit is one of the most instantaneous and destructive events that can occur. The massive release of energy can vaporize conductors, trigger explosions, and pose a lethal threat to personnel. While circuit breakers and fuses are designed to protect against these events, they are useless if they aren’t rated for the fault they are asked to interrupt. This is where a Short Circuit Analysis becomes one of the most critical studies in electrical engineering. For any project manager or facility engineer, understanding its purpose is fundamental to ensuring safety, compliance, and operational reliability.

What Is Short Circuit Analysis?

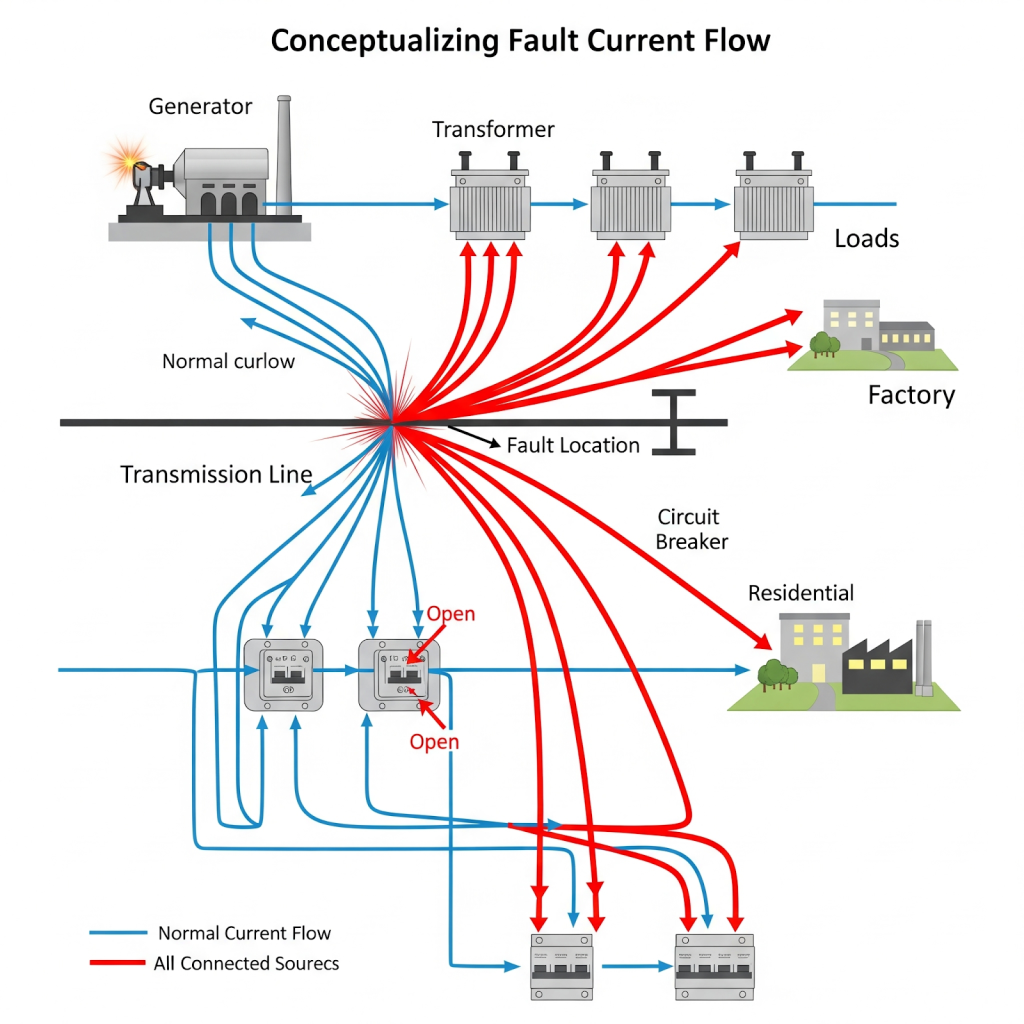

A Short Circuit Analysis (SCA), or fault study, is an engineering study that calculates the potential fault current that could flow at various points within an electrical system. In the event of a fault (e.g., a phase-to-ground or phase-to-phase connection), the current can surge to levels thousands of times higher than the normal operating current. The analysis determines this maximum “available fault current.” The primary goal is to compare this calculated value against the interrupting ratings of your protective devices (circuit breakers, fuses) and the withstand ratings of your equipment (switchgear, panelboards, motor control centers).

In short, the study answers one critical question: “If a short circuit happens here, is our equipment capable of safely handling and interrupting the massive energy release?”

The Critical Objectives of a Short Circuit Study

The importance of a short circuit analysis extends across three pillars of a safe and reliable electrical system.

1. Equipment Protection (Interrupting Rating)

Every piece of protective equipment has a maximum fault current it can safely interrupt, known as its interrupting rating (or Ampere Interrupting Capacity – AIC). If the available fault current exceeds the device’s AIC rating, the device itself can fail violently—exploding and creating a more dangerous situation than the original fault. An SCA verifies that all equipment is properly rated for its position in the system.

Explore Electrical Plant Design Engineering Services in Dubai at Elecwatts

2. Personnel Safety (Arc Flash Analysis)

An SCA is a mandatory prerequisite for performing an Arc Flash Hazard Analysis (as required by NFPA 70E). The amount of energy released in an arc flash event is directly proportional to the available fault current and the time it takes for a protective device to clear the fault. Without the fault current values from the SCA, an arc flash study cannot be completed, leaving personnel exposed to unquantified, life-threatening hazards.

3. System Reliability (Protective Device Coordination)

The results of an SCA are also a critical input for a Protective Device Coordination study. This study ensures that in the event of a fault, the protective device closest to the fault opens first, isolating the problem area without causing a widespread outage. Without knowing the fault current levels, proper coordination is impossible.

Why Your Project Absolutely Needs One

Treating a short circuit study as optional is a significant technical and financial risk.

- Regulatory Compliance: Standards from OSHA, the National Electrical Code (NEC), and NFPA 70E mandate that electrical equipment must not be installed in locations where the available fault current exceeds its rating. A compliant and safe workplace requires a formal study to prove these conditions are met.

- Preventing Catastrophic Failure: An underrated piece of switchgear can and will fail explosively under fault conditions. The resulting damage can lead to extended downtime, costly equipment replacement, and, most importantly, severe injuries or fatalities.

- Cost Avoidance: The upfront cost of a short circuit analysis for industrial projects is negligible compared to the potential costs of an electrical incident, which can include millions in repairs, lost production, litigation, and regulatory fines.

The Process at a Glance for Project Managers

For those overseeing a project, understanding the workflow is key:

- Data Collection: Engineers gather detailed information, including utility fault current availability, transformer impedance data, conductor sizes and lengths, and specifications for all major electrical equipment.

- System Modeling: This data is used to create a comprehensive one-line diagram and build a precise model of the electrical system in specialized software (like ETAP, SKM, or EasyPower).

- Analysis & Reporting: The software calculates the fault duties at every critical point. The final report identifies any equipment with insufficient ratings and provides recommendations for mitigation, such as upgrading breakers or installing current-limiting reactors or fuses.

Frequently Asked Questions (FAQ)

1. When should a short circuit study be performed?

A study is essential for any new construction project before equipment is purchased. It should also be performed whenever there is a major modification to an existing system, such as a utility upgrade, adding a large motor, or installing a generator.

2. What is the difference between a short circuit study and an arc flash analysis?

The arc flash analysis vs short circuit study distinction is crucial: The short circuit study calculates the maximum available fault current. The arc flash analysis uses that fault current value (along with device clearing times) to calculate the incident energy, which determines the required personal protective equipment (PPE). The SCA is a necessary input for the arc flash study.

3. What does “interrupting rating” (AIC) mean?

Ampere Interrupting Capacity (AIC) is the maximum current that a fuse or circuit breaker can safely interrupt without failing or exploding. It is a critical safety rating for protective devices.

4. What happens if we don’t perform a short circuit analysis?

You are operating with unverified risks. Your equipment may not be rated to handle a fault, which can lead to explosive failures, extended downtime, regulatory fines for non-compliance, and severe personnel injury.

5. How often should a short circuit study be updated?

Industry best practice (as per NFPA 70E) recommends reviewing, and updating if necessary, the study at least every five years, or any time a significant change is made to the electrical system.

Conclusion

A Short Circuit Analysis is not a discretionary add-on; it is a foundational element of safe, reliable, and compliant electrical system design and operation. It provides the essential data needed to protect multi-million dollar assets and, more importantly, the lives of the people who work with them. By verifying that your equipment can withstand the worst-case scenario, you are making a critical investment in your project’s long-term success and safety.

Ensure your facility is protected. Contact Elecwatts to discuss our comprehensive power system studies and how we can help you achieve a safer, more reliable electrical infrastructure.