Introduction: The Make-or-Break Gate

Imagine this: Your project’s foundation is poured, steel is rising, and the finish line seems within reach. Then, the letter arrives. The utility has rejected your connection application. Key studies are missing, drawings are non-compliant, and the entire electrical design requires resubmission. Suddenly, your opening date is pushed back six months. Leases are jeopardized, revenue is lost, and stakeholders are furious. Why? Because utility approval was treated as a final administrative checkbox, not a foundational technical prerequisite.

In the GCC, securing power from the national or local utility is not just paperwork; it’s a rigorous technical and procedural marathon that can dictate your project’s entire timeline and budget from day one. Authorities like DEWA (Dubai), ADDC (Abu Dhabi), SEC (Saudi Arabia), and KAHRAMAA (Qatar) uphold world-class, stringent standards. Their mandate is grid stability and safety, and they subject every new connection to meticulous scrutiny. Navigating this process successfully requires more than just an electrical engineer, it demands a specialist who speaks the utilities’ language.

The GCC Utility Approval Process: A High-Level Roadmap

While each utility has its own specific procedures and portals (like DEWA’s Bayti or KAHRAMAA’s Kahramaa), the journey follows a universal four-phase structure.

- Phase 1: Initial Application & Feasibility (The “No Objection”). This is the project registration, where you submit initial load details and site information. The utility provides a “No Objection” or initial approval, along with critical data like the designated connection point and, most importantly, the grid’s available fault current level, a number that will shape your entire design.

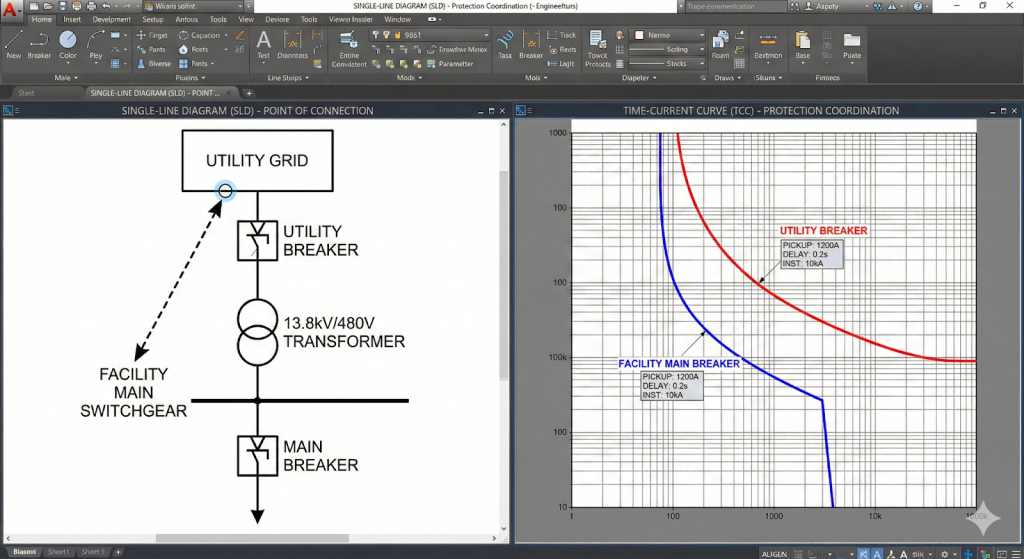

- Phase 2: Detailed Design & Study Submission (The Technical Heart). This is the core of the battle. You must develop and submit a complete, utility-grade design package. This includes detailed single-line diagrams, layout drawings, equipment specifications, and, most critically, a suite of mandatory power system studies (explained below). This package is your formal technical proposal to the grid.

- Phase 3: Review, Compliance, and NOC Issuance. The utility’s engineering team conducts a thorough audit of your submission. They will check every calculation, every study result, and every drawing for compliance with their Green Books, Regulations, and Standard Specifications. Queries (RFIs) are common. Success here yields the coveted No-Objection Certificate (NOC) or Connection Agreement.

- Phase 4: Construction Supervision & Final Connection. With NOC in hand, construction can begin. However, utilities often require witness testing of primary equipment and final inspection before the physical connection to their network is made.

Crucially, Phases 2 & 3 are where 90% of the engineering effort and risk reside. This is where projects are won or lost.

At Elecwatts we offer the best electrical plant design engineering services in UAE. Get in touch for a quote.

The Non-Negotiable Technical Studies: Your Ticket to Approval

This suite of analyses is non-negotiable. They are the mathematical proof that your project will be a good citizen on the grid. Submitting them in the correct utility-specific format is mandatory.

- Load Flow Analysis: This isn’t just a load schedule. It’s a dynamic model proving your facility’s demand profile won’t cause unacceptable voltage drops or overload the utility’s distribution transformers and feeders under various operating conditions.

- Short-Circuit Study: Arguably the most critical study. Using the utility-provided fault current, you must prove that every piece of switchgear, from the main MV panel down to distribution boards, has an interrupting and withstand rating sufficient to survive a fault safely. Underestimating this is a catastrophic, rejection-level error.

- Protection Coordination Study: This study is your “selective tripping” plan. It uses time-current curves to demonstrate that a fault in your building will be cleared by your own breaker only, isolating the problem without causing a nuisance trip upstream on the utility’s grid. It’s a key requirement for grid reliability.

- Harmonic Analysis: For projects with significant non-linear loads (VFDs, LED lighting, data centers, etc.), this study proves that your harmonic filtering is adequate. The goal is to prevent harmonic currents from polluting the power quality for other utility customers, which can damage sensitive equipment across the network.

At ElecWatts, we don’t just run these studies; we engineer them to the exact submission standards of DEWA, SEC, KAHRAMAA, and other GCC utilities, ensuring first-pass acceptance.

Common Pitfalls That Derail Applications (And How to Avoid Them)

- Pitfall 1: Submitting Conceptual Designs. Utilities require construction-ready details. Sending schematic or preliminary drawings guarantees a rejection and resets the review clock.

- Avoidance: Develop the complete, coordinated design package from the outset, with all vendor-agnostic technical data specified.

- Pitfall 2: Blindly Applying International Standards. Using IEC, NEC, or IEEE without applying the local utility amendments is a sure path to failure. GCC utilities have specific deviations (e.g., cable derating factors, grounding requirements, equipment certifications).

- Avoidance: Design from the utility’s regulation document first, using international standards as a supporting reference.

- Pitfall 3: Underestimating Fault Current. Using generic or assumed fault levels leads to undersized, non-compliant switchgear that will fail the short-circuit study.

- Avoidance: Base your entire design on the official fault current data provided by the utility in Phase 1.

- Pitfall 4: Poor Documentation. Incomplete data schedules, unlabeled drawings, or studies in a non-preferred format trigger endless queries and delays.

- Avoidance: Follow the utility’s submission checklist and drawing format (layer standards, title blocks, etc.) to the letter.

Conclusion: Your Strategic Advantage, Partnering with a Specialist

The GCC utility connection process is, in essence, a de facto technical audit of your project’s entire electrical design. Navigating it successfully requires a blend of foresight, precise engineering, and often, knowledge of the unwritten preferences and precedents within each utility’s review department.

Trying to manage this internally or through a generalist consultant turns this critical path into a critical risk.

Don’t let utility approvals become your project’s critical path.

ElecWatts specializes in preparing the complete, compliant package of power system studies and design documents that GCC utilities require. We speak their language, we know their standards, and we engineer for acceptance.

Contact us today for a [pre-application feasibility review] to de-risk your project timeline and budget from day one. Let’s secure your power, so you can focus on building everything else.

FAQs: Navigating GCC Utility Connection Approvals

1. Our project’s electrical consultant is handling the design. Why would we need a separate specialist for utility approvals?

While many consultants can produce a code-compliant design, GCC utilities have highly specific submission standards, formats, and unwritten preferences that go beyond generic IEC/NEC compliance. A specialist like ElecWatts acts as your dedicated translator and liaison. We ensure the design package, especially the mandatory studies, is presented in the exact format the utility reviewers expect, dramatically increasing your chance of first-pass approval and preventing costly rounds of queries and resubmissions.

2. How early in the project should we engage a utility connection specialist?

The earlier, the better, ideally during the conceptual design phase. The most critical piece of information, the utility’s available fault current at your connection point, is obtained in Phase 1. This number dictates your entire switchgear specification. Engaging us at this stage allows us to guide the fundamental design choices, ensuring they are aligned with utility requirements from the start. Retro-fitting a design to meet utility standards is far more expensive and time-consuming.

3. Can’t we just use the power system studies from a similar previous project to save time and cost?

This is one of the most common and costly mistakes. Every utility connection point is unique in terms of available fault current, grid stiffness, and protection requirements. Furthermore, utility standards are frequently updated. Submitting studies from an old or different project is a guaranteed red flag for reviewers and will lead to immediate rejection. All studies must be project-specific, based on current utility data, and dated within the validity period required by the authority.

4. What’s the single biggest reason utility applications get rejected or delayed?

The number one cause is submitting incomplete or non-compliant technical studies, particularly the Short-Circuit and Protection Coordination studies. Underestimating the fault current or failing to demonstrate selective coordination with the utility’s upstream protection are critical failures. The second major cause is drawings that lack utility-required details, such as specific equipment labels, cable sizing calculations, or the correct layer standards in CAD files.

5. If we get the No-Objection Certificate (NOC), is the utility’s involvement over?

No. The NOC is your permission to build the system as approved. The utility will remain involved through construction supervision and final inspection. They often require witness testing for major equipment (like transformer and breaker commissioning) and a final site inspection before authorizing the physical connection (“landing the cable”) and energization. Any deviation from the approved design during construction can nullify the NOC and force you to restart the approval process.