The Silent Failure During a Crisis

Imagine this scenario: A small 10kW motor in your HVAC system develops a winding fault. In a properly designed system, the small breaker directly feeding that motor should trip instantly, isolating the problem while the rest of the facility hums along unaware.

Instead, the lights go out. The production line stops. The silence is deafening.

A fault that should have been a minor maintenance ticket has escalated into a total facility blackout because the main distribution breaker tripped before the local breaker could react. This is a classic failure of Protection Coordination. Think of coordination as your facility’s “electrical immune system.” Just as your body isolates an infection to keep the rest of the organism healthy, a coordinated electrical system isolates a fault to the smallest possible area. When that immune system is compromised, a minor “infection” can kill the “patient.”

What is Protection Coordination (And Why Does It Degrade?)

At its core, protection coordination (or selective coordination) is the science of timing. It ensures that protective devices, relays, fuses, and breakers, operate in a specific sequence. The device closest to the fault must trip first.

Many facility managers believe this is a “set-and-forget” system. Once commissioning is done, they assume the settings are correct forever. This is a dangerous misconception. The “safety net” degrades over time due to:

- System Changes: Over the years, new loads are added, motors are swapped for larger ones, or solar PV is integrated. These changes alter the fault currents, rendering the original settings obsolete.

- Improper Settings: In many GCC projects, rushed commissioning leads to contractors leaving relays on “factory default” settings or making “educated guesses” rather than following a calculated engineering study.

- Lack of an Updated Study: If your last protection coordination study is more than 5 years old, it is likely irrelevant. The grid has changed, and your facility has changed.

Symptoms of Poor Coordination in Your GCC Plant

How do you know if your electrical immune system is failing? The symptoms are often dismissed as “glitches” until a major failure occurs.

- Nuisance Tripping: Breakers trip during motor startups or seemingly for no reason. This often indicates settings are too sensitive or curves are overlapping.

- Cascading Outages: As described in the intro, a downstream fault causes an upstream breaker to trip. This is a complete lack of selective coordination.

- Failed Selective Operation: Similar to cascading, but specifically when a larger feeder trips instead of a branch circuit, taking out multiple healthy loads unnecessarily.

- Increased Arc Flash Hazards: Mis-coordinated relays often react too slowly to faults. Slower tripping time means the arc flash energy has more time to build, drastically increasing the danger to personnel and requiring higher-level PPE.

The 4-Step Protection Coordination Health Audit

At Elecwatts, we treat this as a health checkup for your facility. We don’t just guess; we audit.

1. Data Mining

We start by collecting the “patient history.” This involves gathering existing single-line diagrams, old test reports, and manufacturer data sheets for your breakers and relays.

2. Field Verification

Paperwork is rarely 100% accurate. Our engineers go on-site to visually verify the installed equipment and, crucially, to download the current settings from your digital relays and trip units. We often find settings that were changed by maintenance staff years ago and never documented.

3. Simulation & Analysis

We build a digital twin of your system using industry-standard software like ETAP or SKM. We run fault simulations to see how your protective devices interact. This highlights exactly where the curves overlap and where the “blind spots” are.

4. Reporting & Remediation Plan

We deliver a clear, actionable report. It doesn’t just show the problems; it provides a prioritized list of relay setting adjustments and, if necessary, hardware upgrades to restore full selectivity and reliability.

Conclusion: Prevent the Domino Effect

Protection coordination is not a luxury; it is the operational logic that keeps your plant running. It is a living part of your electrical infrastructure that requires periodic review, especially after any modification. Neglecting it turns every minor short circuit into a game of Russian Roulette with your uptime.

Frequently Asked Questions (FAQ)

1. How often should a protection coordination study be performed?

Industry standards (like NFPA 70B) recommend a review every 5 years. However, a study is mandatory immediately following any significant change to the electrical system, such as adding large motors, replacing a transformer, or installing a backup generator.

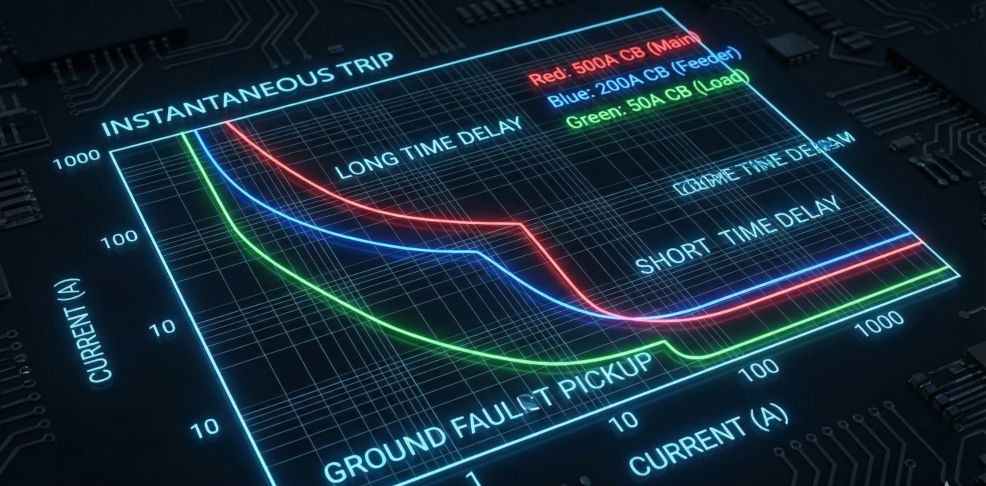

2. What are Time-Current Curves (TCC)?

TCCs are the graphical representation of a breaker’s performance. They plot “Time” against “Current.” Ideally, the curves of downstream devices should be to the left and below the curves of upstream devices, ensuring they trip faster without overlapping.

3. Why are “factory default” settings dangerous?

Factory defaults are typically set to the minimum or maximum values, not the values your specific system needs. Leaving a relay on default is like driving a car with the seat adjusted for someone else, it might work, but it’s dangerous in an emergency.

4. Can better coordination reduce Arc Flash levels?

Yes, significantly. If we can adjust the settings to trip the breaker faster without causing nuisance trips, we reduce the duration of the arc fault. Less time equals less energy, which can lower the required PPE level and save lives.

5. Do I need specialized software for this?

For any modern industrial or commercial facility, yes. The complex interaction of multiple fault sources and adjustable trip units is mathematically impossible to coordinate accurately by hand. Software like ETAP is essential for a valid study.

Is your electrical immune system compromised?

Don’t wait for a major outage to find out Elecwatts Protection Coordination Audit identifies weak points and provides a clear roadmap to reliability.