In any major infrastructure or industrial project, the intricate network of cables is the lifeblood that powers critical systems. Yet, too often, cable design is treated as an afterthought, leading to costly delays, safety hazards, and operational inefficiencies. For project managers, a foundational understanding of cable design engineering isn’t just beneficial—it’s essential for steering a project to success. This guide provides clarity on the fundamentals, highlights key decision-making pointers, and outlines best practices to ensure your project’s electrical infrastructure is robust, compliant, and future-proof.

What Is Cable Design Engineering?

Cable design engineering is the specialized discipline focused on the systematic planning, selection, and routing of electrical cables and their associated infrastructure. It goes far beyond simply connecting Point A to Point B; it is a comprehensive process that ensures power and data are transmitted safely, efficiently, and reliably throughout a facility’s lifecycle.

The scope of this discipline involves several critical components:

- Material Selection: Choosing the appropriate conductors (e.g., copper, aluminum), insulation, and sheathing based on electrical loads, environmental conditions, and budget.

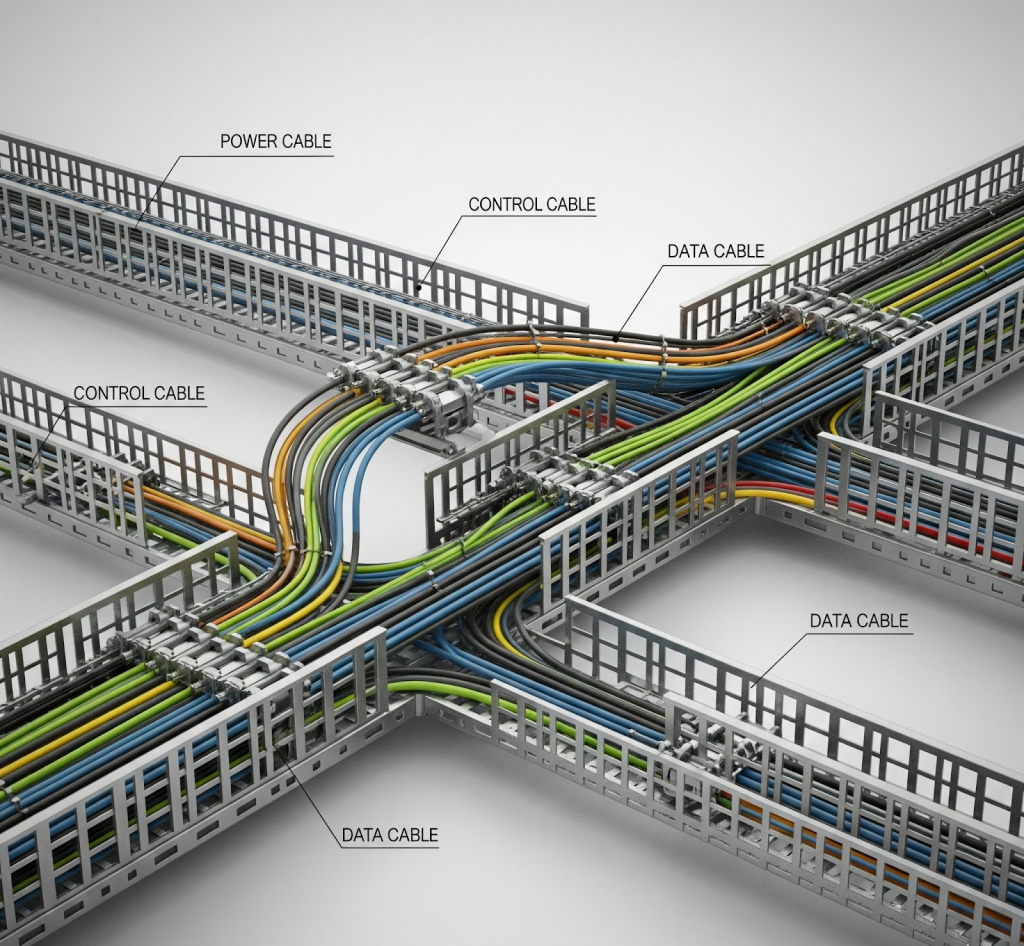

- Routing Strategies: Designing logical and efficient pathways for cables using trays, conduits, or direct burial methods to prevent electromagnetic interference (EMI), ensure accessibility for maintenance, and optimize material usage.

- Safety Standards: Adhering to rigorous local and international codes, such as the National Electrical Code (NEC) or IEC standards, to guarantee the safety of personnel and equipment.

- Load Calculations: Performing detailed calculations to determine the required cable size (ampacity) to handle electrical loads without overheating.

- Environmental Considerations: Accounting for factors like temperature, moisture, chemical exposure, and mechanical stress that can impact a cable’s performance and longevity.

Key Principles of Cable Design Engineering Every Project Manager Should Know

While you don’t need to be a cable engineer, understanding these core principles will empower you to ask the right questions and make informed decisions.

Understanding Loads and Capacity

One of the most critical aspects of cable design engineering is ensuring that a cable can handle the electrical current it’s intended to carry. This is known as ampacity. Under-sizing a cable is a significant fire hazard, while over-sizing it leads to unnecessary material costs. Project managers should ensure that engineering teams have accounted for peak loads, potential future growth, and voltage drop over long distances.

The Importance of Safety Codes and Standards

Non-compliance with electrical codes is a non-negotiable risk. These standards dictate everything from cable spacing and insulation requirements to fire-stopping and grounding techniques. A project manager’s role is to verify that all design and installation work is planned and executed in strict accordance with the relevant regulatory bodies. This prevents legal issues, ensures safety, and facilitates smooth project commissioning.

Selecting the Right Materials

The choice of conductor, insulation, and sheathing materials is a crucial decision with long-term consequences.

- Conductors: Copper is the standard for conductivity and flexibility, while aluminum may be a cost-effective alternative for larger feeder cables, provided proper termination techniques are used.

- Insulation: Materials like PVC, XLPE, and EPR offer different thermal properties and resistance to moisture and chemicals. The choice depends entirely on the operating environment.

- Sheathing/Jacket: The outer layer protects the cable from mechanical damage, UV radiation, and chemical corrosion.

The Importance of Future-Proofing and Scalability

In today’s fast-paced industrial landscape, what is sufficient today may be inadequate tomorrow. A good cable design accounts for future expansion. This might involve installing spare conduits, upsizing cable trays, or selecting cables with a higher capacity than immediately required. While this may involve a slightly higher initial investment, it saves significant time and money on future retrofits.

Common Mistakes and How to Avoid Them

Understanding the fundamentals of cable design helps prevent common pitfalls that can derail a project.

- Improper Routing: Poorly planned cable routing best practices in industrial projects can lead to signal interference (crosstalk) between power and data cables, make maintenance nearly impossible, and violate bend radius requirements, damaging the cables.

- How to Avoid: Insist on detailed routing diagrams from the engineering team that segregate cable types and ensure accessibility.

- Ignoring Environmental or Thermal Factors: A cable’s ampacity is rated for a specific ambient temperature. In hot environments or when bundled with other heat-producing cables, its capacity is derated. Ignoring this can lead to overheating and premature failure.

- How to Avoid: Ensure that thermal calculations and derating factors are applied, especially in industrial settings with high-temperature zones.

- Failing to Align with Regulatory Requirements: Each jurisdiction may have specific amendments to national codes. Assuming a one-size-fits-all approach is a recipe for failed inspections and rework.

- How to Avoid: Engage a local engineering consultant familiar with the regional regulatory landscape early in the planning phase.

A Step-by-Step Planning Guide for Project Managers

Knowing how to plan cable design in engineering projects is a key managerial skill. Follow this structured approach.

1. Pre-Design Checklist

Before detailed engineering begins, ensure you have answers to these questions:

- What are the primary electrical loads?

- What are the environmental conditions (temperature, chemical exposure)?

- What is the expected level of future expansion?

- What are the relevant local codes and standards?

2. Collaboration with Electrical/Cable Engineers

Establish clear communication channels from day one. Your role is to provide the engineers with the overall project scope, budget constraints, and schedule, while their role is to deliver a design that meets those requirements safely and efficiently.

3. Tools and Documentation to Aid Planning

Request and review key documents throughout the project lifecycle:

- Single-Line Diagrams (SLDs): To understand the overall power distribution.

- Cable Schedules: A comprehensive list of all cables, their types, sizes, and routes.

- Tray and Conduit Layouts: To visualize the physical installation.

4. Coordination with Procurement and Installation Teams

The design is only as good as its execution. Ensure the procurement team orders the exact materials specified and that the installation team fully understands the routing plans and quality standards.

Integrating Cable Design with Project Management Workflows

Finally, seamlessly integrate cable design into your existing project management framework.

- Communicating with Engineering Teams: Schedule regular review meetings to track progress against the project schedule. Use a risk register to log any potential design issues.

- Incorporating Design Considerations into Project Schedules: Cable installation is often a critical path activity. Ensure your project timeline allocates sufficient float for design reviews, procurement lead times, and installation.

- Risk Management Strategies: Identify potential risks early. What if a specified cable is on a long lead time? What if a physical obstruction is discovered on-site? Have contingency plans ready to mitigate these issues without impacting the project deadline.

Conclusion

Cable design engineering is a complex and critical element of any successful project. For project managers, a proactive approach grounded in the fundamentals of loads, safety, materials, and planning is the best way to prevent costly errors and ensure a robust, reliable electrical system. By fostering collaboration with your engineering teams and integrating these principles into your workflow, you can confidently navigate the technical challenges and deliver projects on time and within budget.

Ready to ensure your next project’s electrical infrastructure is expertly designed? Contact Elecwatts for tailored cable design support or download our comprehensive cable planning checklist for project managers.

Frequently Asked Questions (FAQ)

- What is the difference between ampacity and voltage drop?

Ampacity is a cable’s maximum current-carrying capacity without exceeding its temperature rating, ensuring it doesn’t overheat. Voltage drop is the reduction in electrical potential along the path of a current, which becomes significant over long distances and can cause equipment to malfunction if not properly calculated. Both are critical for correct cable sizing.

- Why is segregation of different cable types so important?

Segregating cables—specifically keeping power cables separate from instrumentation or data cables—is crucial to prevent electromagnetic interference (EMI). High-voltage power cables create magnetic fields that can induce “noise” in low-voltage data signals, leading to corrupt data and unreliable control system performance.

- How early in a project should cable design be considered?

Cable design should be considered during the initial design and layout phase of a project. Early planning allows for the allocation of adequate space for cable trays and conduits, helps in coordinating with other disciplines (like mechanical and civil), and prevents costly rework or routing challenges that arise when it’s treated as an afterthought.

- What are the main project management trade-offs between using copper vs. aluminum conductors?

The primary trade-off is cost versus performance. Aluminum is significantly cheaper and lighter than copper, making it attractive for large feeder cables. However, it is less conductive, requires a larger cross-sectional area for the same ampacity, and is more prone to oxidation at connection points, requiring specialized termination procedures. Copper offers superior conductivity and reliability, but at a higher cost.

- Can the same cable be used for both indoor and outdoor installations?

Not usually. Outdoor cables require specific properties that indoor cables often lack, such as a UV-resistant jacket to prevent degradation from sunlight, enhanced moisture resistance (often with water-blocking tapes or gels), and a wider operating temperature range. Using an indoor-rated cable outdoors will lead to premature failure and safety hazards.